Molendum machina principaliter apta est ad molendinum processus metallurgiae, materiae aedificiorum, industriae chemicae, fodinae et aliorum mineralium materiae. Potest molere calcis lapidem, calcitem, calcii oxydum, calcii hydroxidum, quartzum, feldsparum, talcum, baritum, fluoritem, rarae terrae, marmor, ceramica, bauxitem, manganese ore, ferrum ore, auri ore, fosfati ore, ferrum oxydum rubrum, zirconii sabulum, caementum, aqua granulatam caementi, clinker cementi, carbonem activatum, dolomitem, granite, garnetum, ferrum oxydum flavum, placenta soyae, fertiliserum chemicum, fertiliserum compositum, cinis volans, carbo bituminis, carbo coking, lignitum, rhodochrositem, oxydum chromii viridis, aurum, rubrum lutum, lutum, kaolinum, coke, gangue, china lutum, bluestone, fluorite, bentonitem, lapis medicus, rhyolite, viridescens lapis, pyrophyllite, shale, purpura harenae, chlorite, multiplices lapides, basaltum, gypsium, graphite, carbides silici, materies insulationis thermalis et omnium generum mineralium quae non sunt inflammabiles et explosivae, quarum Moh s duritia sub 7 gradu et aqua contentum sub 6%. Granulatio producti confecti potest inter 0.25 et 0.023 millimetra (aequivalens 60 rete et 600 rete) secundum diversas exigentias.

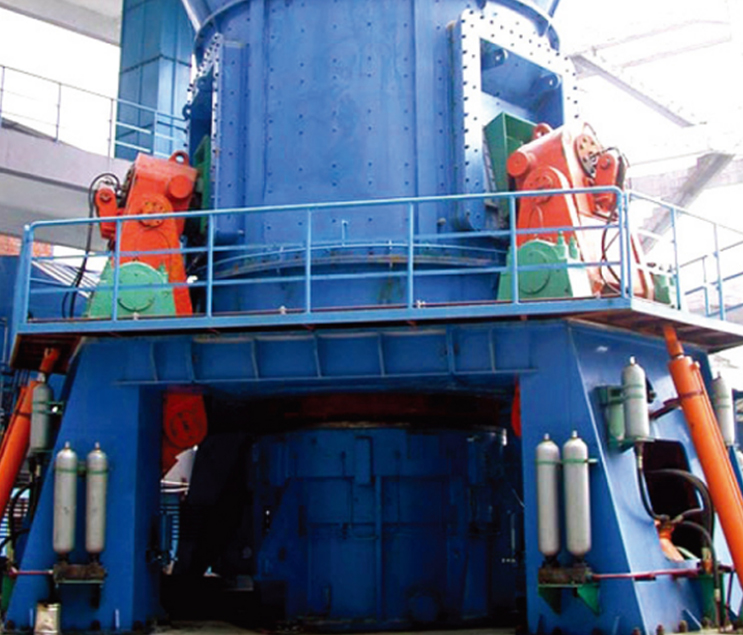

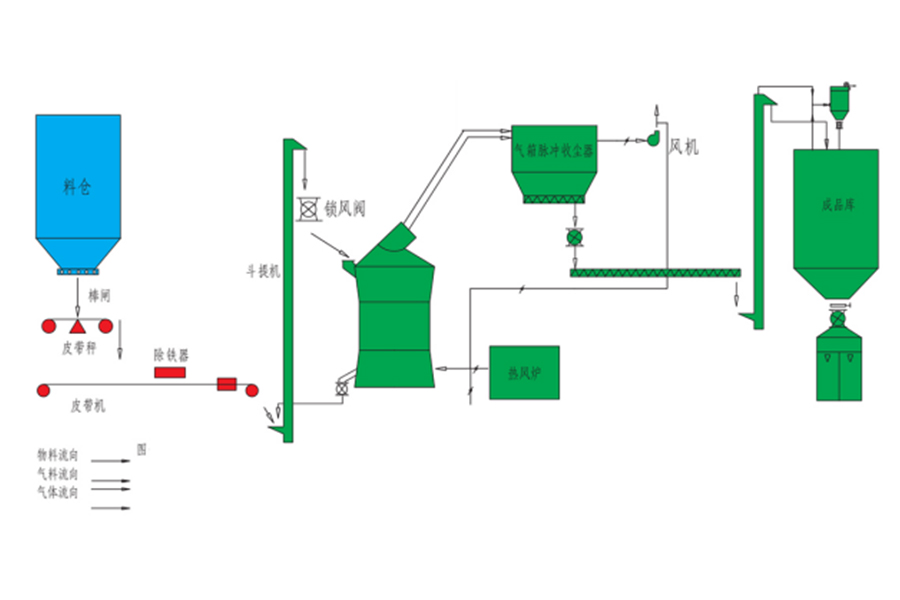

The grinding mill is mainly suitable for grinding processing of metallurgy, building materials, chemical industry, mining, and other mineral materials. It can grind limestone, calcite, calcium oxide, calcium hydroxide, quartz, feldspar, talcum, barite, fluorite, rare earth, marble, ceramic, bauxite, manganese ore, iron ore, copper ore, phosphate ore, iron oxide red, zircon sand, slag, water granulated slag, cement clinker, activated carbon, dolomite, granite, garnet, Iron oxide yellow, soybean cake, chemical fertilizer, compound fertilizer, fly ash, bituminous coal, coking coal, lignite, rhodochrosite, chromium oxide green, gold, red mud, clay, kaolin, coke, gangue, china clay, bluestone, fluorite, bentonite, medical stone, rhyolite, greenstone, pyrophyllite, shale, purple sands, chlorite, multiple rocks, basalt, gypsum, graphite, silicon carbide, thermal insulation materials and all kinds of non-flammable and explosive mineral materials which Moh's hardness is below 7 grade and water content below 6%. The granularity of the finished product can be adjusted between 0.25 and 0.023 millimeters (equivalent to 60 mesh and 600 mesh) according to different requirements.