In competitive landscape of industriae pulveris processus, industria efficientiam est non iustus a perficientur metric-suus 'a decreta factor in operational profitability et environmental obsequio. In Vertical molendis molendini Praecipue provectus exempla quasi lyh1008 series, ludit a centralis munus in achieving hoc statera per integrating innovative consilio features quod significantly redigendum virtutem consummatio cum maintaining altum throughput. Systems optimize industria usum non solum adiuvat operators facere certiorem faciant sed etiam positiones manufacturers qui offerunt talis apparatu ut deinceps cogitandi principes in sustineri productio.

Unum ex maxime impactfuls strategies usus est in modern vertical molendini molendinas est scelerisque integration, ubi vastum calor ab aliis processibus aut ambientium aer est usus ad excoquatur rudis materiae intra molendini. Hoc reduces opus additional calefactio elementa et lowers altiore industria input. In the LYH1008 model, an optimized airflow path ensures even heat distribution, allowing moisture-laden feedstock to be dried efficiently without compromising grinding performance—a key advantage over traditional ball mills that often require separate drying units.

Motricium et coegi technologiae et evolved ad augendae industria efficientiam vertical molendini molendini operationes. Maximum efficientiam Motors cum variabilis frequency agit (VFDS) patitur pro precise imperium super gyratoris celeritate et torque, accommodet ad fluctuans onus condiciones in realem tempus. Hoc dynamic temperatio impedit necesse industria spicis et extendat motricium vitae. Praeterea, regenerative braking systems, ubi convenit, can recuperandam aliqua motu navitas in shutdowns vel celeritate reductiones, porro meliorem ratio scriptor altiore industria profile.

Airflow Optimization intra mola cubiculum confert signanter ad industria peculi. Per minimizing pressura damna per streamlined ducens et improved classifier consilia, vertical molendini molendini potest ponere altum internum circulationem rates cum reducitur fan potentia. Et lyh1008 integrates aerodynamic enhancements quod inferior resistentia et curare lenis materia onerariis, reducendo onus in auxilia systems et conlatis ad magis industria, conscius operationem.

Intelligentes potestate systems sunt alium angularem de industria-agentibus vertical molendis molendini setups. Hi systems Monitor variables ut pascat rate, pressura, temperatus et particula magnitudine in realem tempus, adjusting parametri automatice ponere bene perficientur. In lyh1008 hoc gradu automation permittit consistent output qualis dum vitandum super-molere aut underutilizatione, utrumque ducunt vastata industria. Nam customers, hoc modo inferior operational costs et major predictability in productionem cycles.

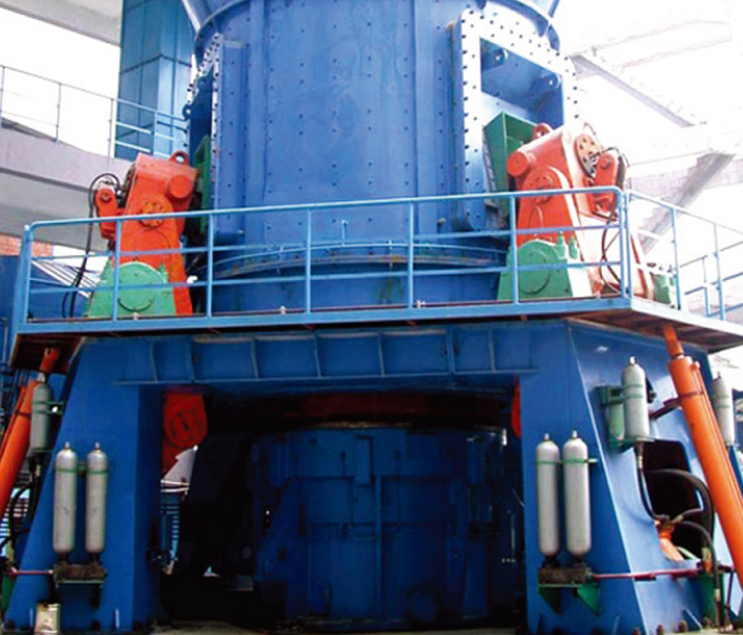

Ultra recta industria, salvis machinationes, in altiore mechanica efficientiam Vertical molendis molendini ne despicias. Cum paucioribus movere partes et pacto structuram, verticalis mola in se devorabit minus industria quam horizontali versari. Et LyH1008 Praeterea enhances hoc utilitatem gere, repugnans components et humilis-friction gestus ut minimize mechanica damna. Cum combined, haec features translate in measurable pretium reductiones per lifecycle in apparatu.

Nam pulveris processus businesses aiming manere praemisit in utroque oeconomica et environmental termini, eligens an industria-efficiens vertical molendini molendini sicut lyh1008 est opportuna moventur. Hoc reflects commitment ad innovation, sustineri, et diu term valorem-qualitatibus, quod discretionem buyers respicere cum circumsedere in industriae apparatu. Ut global demanda pro fine pulveris continues ad oriri, sic est momenti intelligentes, industria, conscius vestibulum solutions.